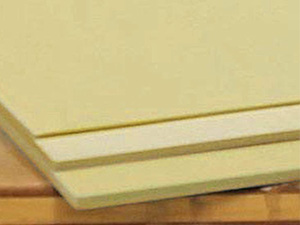

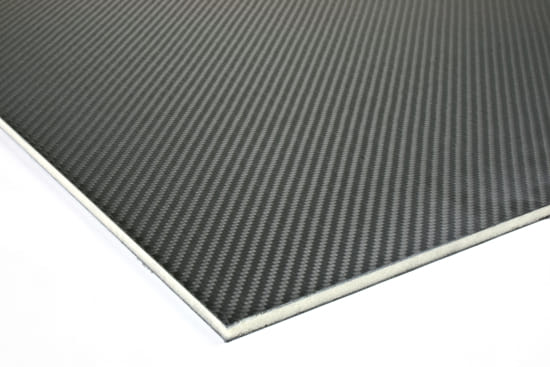

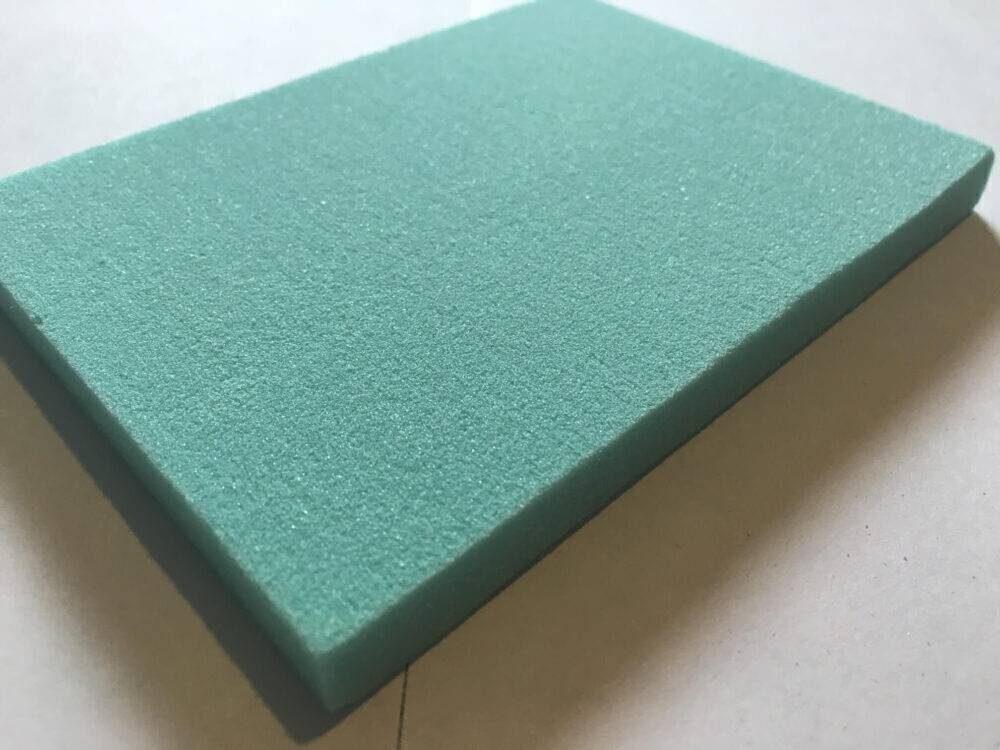

Foam is most frequently used as structural core material for composite laminates delivering added strength stiffness and insulation without adding weight.

Fiberglass foam core sheets.

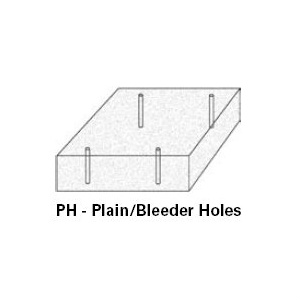

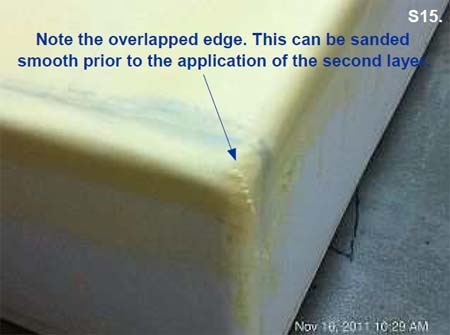

Generally it is easy to handle readily conforms to shapes and can be bonded in layers to add thickness.

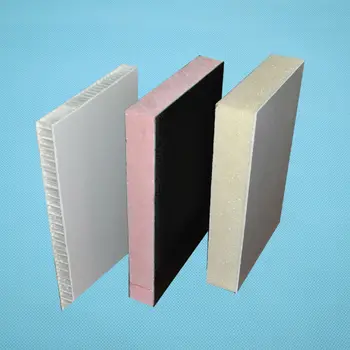

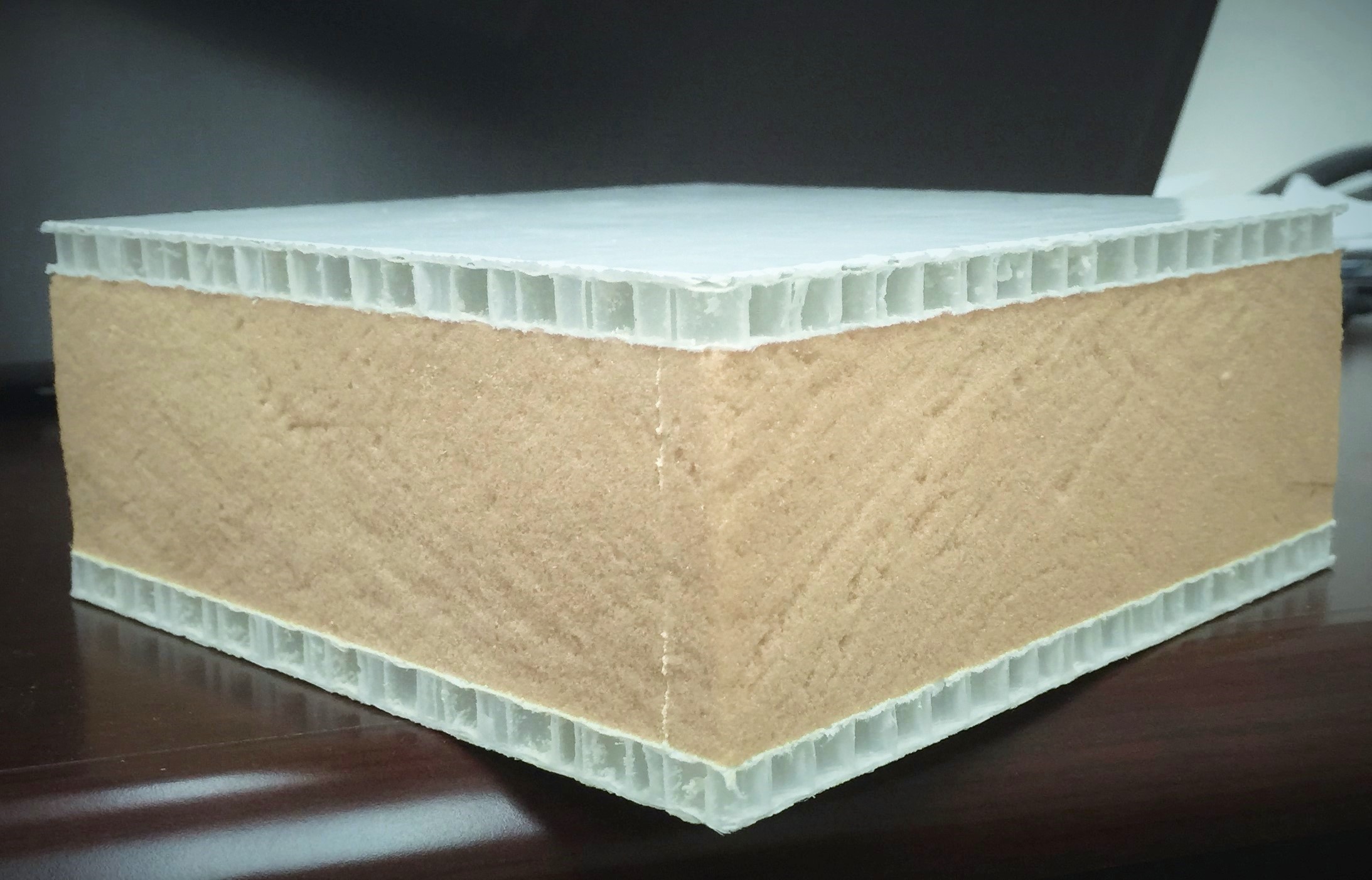

Core materials are a great way to stiffen a composite structure without adding a lot of weight.

Anywhere light weight stiffness and good weather resistance and durability is required.

Cockpit and salon tables hatch covers fish boxes settee tops non structural partitions and bulkheads swim ladders sliding doors for fish boats.

It is the true structural sandwich panel.

Cladfoam polyisocyanurate foam core structural panels consider fiber tech s structural insulated fiberglass panels when your project requires strength durability and superior exterior interior finishes in a one piece panel design.

21 abrasives 25 brushes rollers pans 19 boat parts and accessories 18 caulking 1 clothing 54 detailing 47 epoxy resin and glue 35 fiberglass 8 foam core material 16 gel coat 3 hardware 3 hardeners 23 mold fabrication 51 paint 8 polyester resins 25 putty fillers 22 safety 9 solvents 13 measuring mixing 9 tape 2 trims and seals 26 tools 3 vinyl.