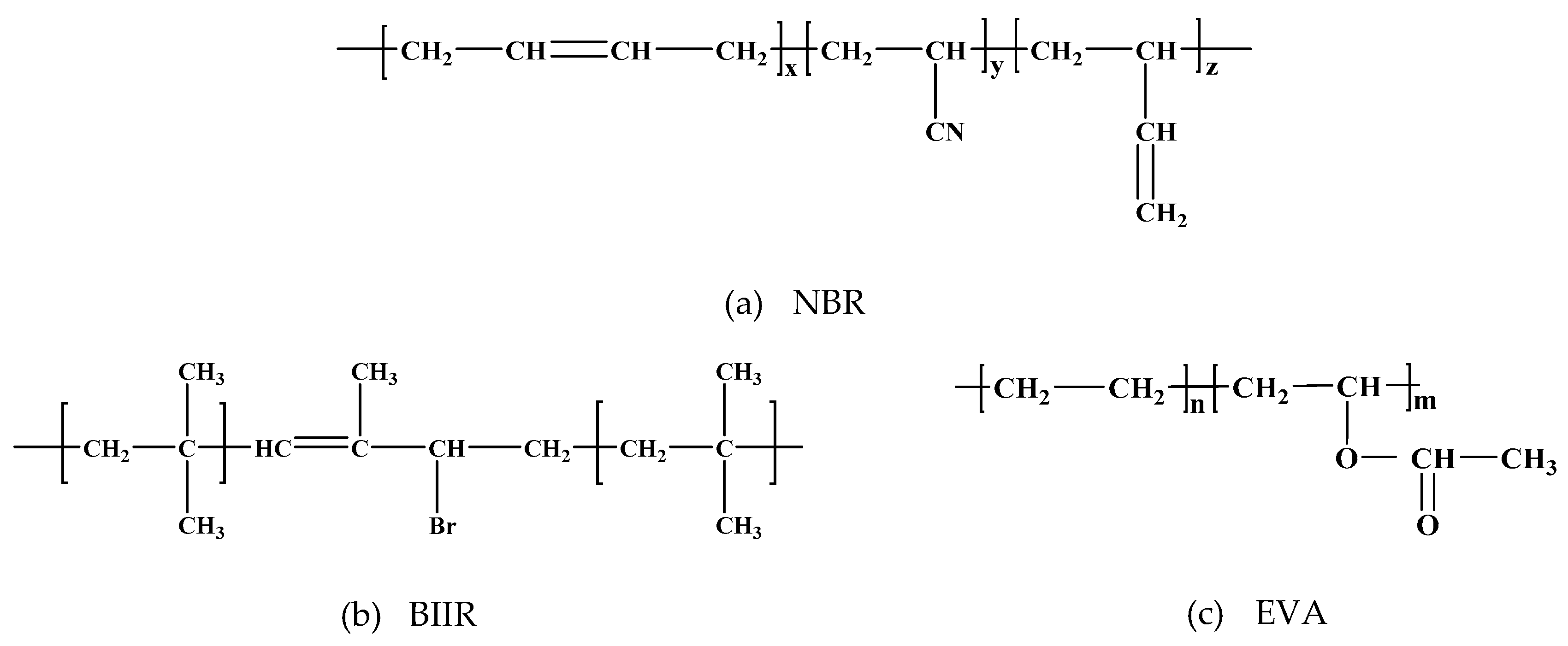

A prior extensive experimental phase identified those variables that are most important for ethylene vinyl acetate emulsion copolymer production.

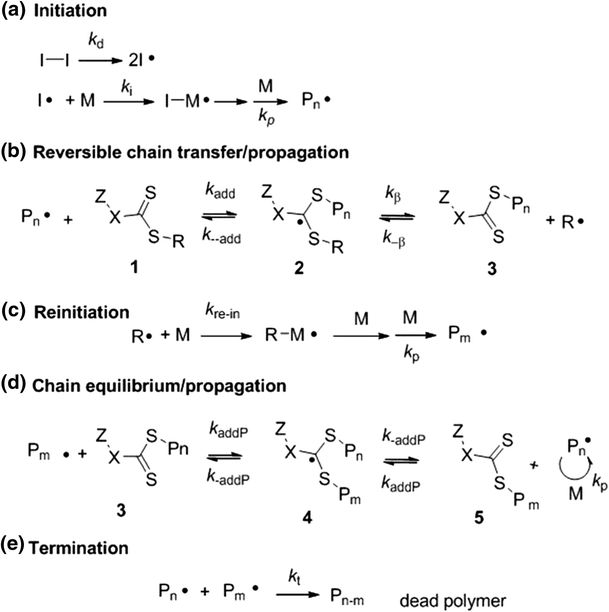

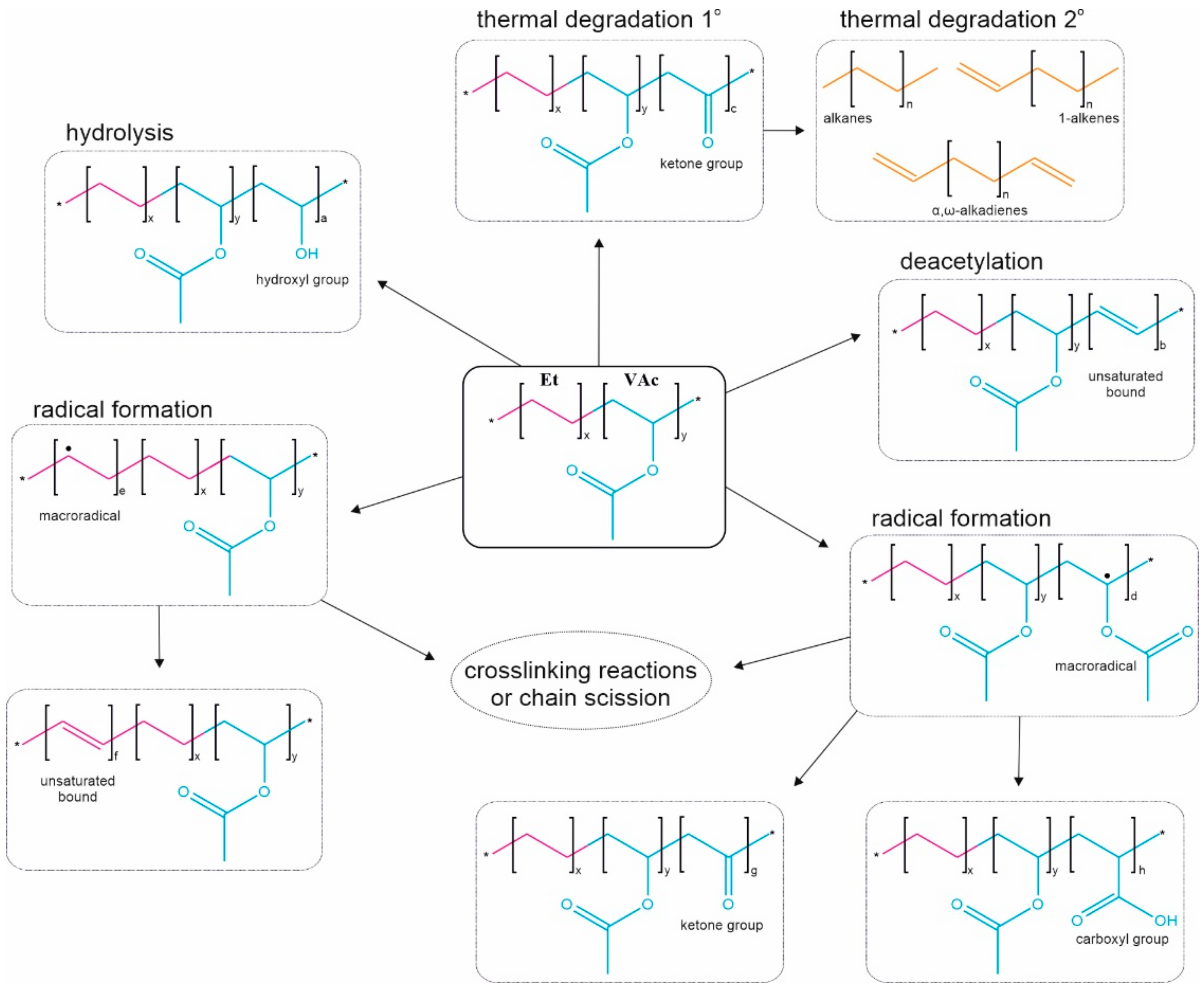

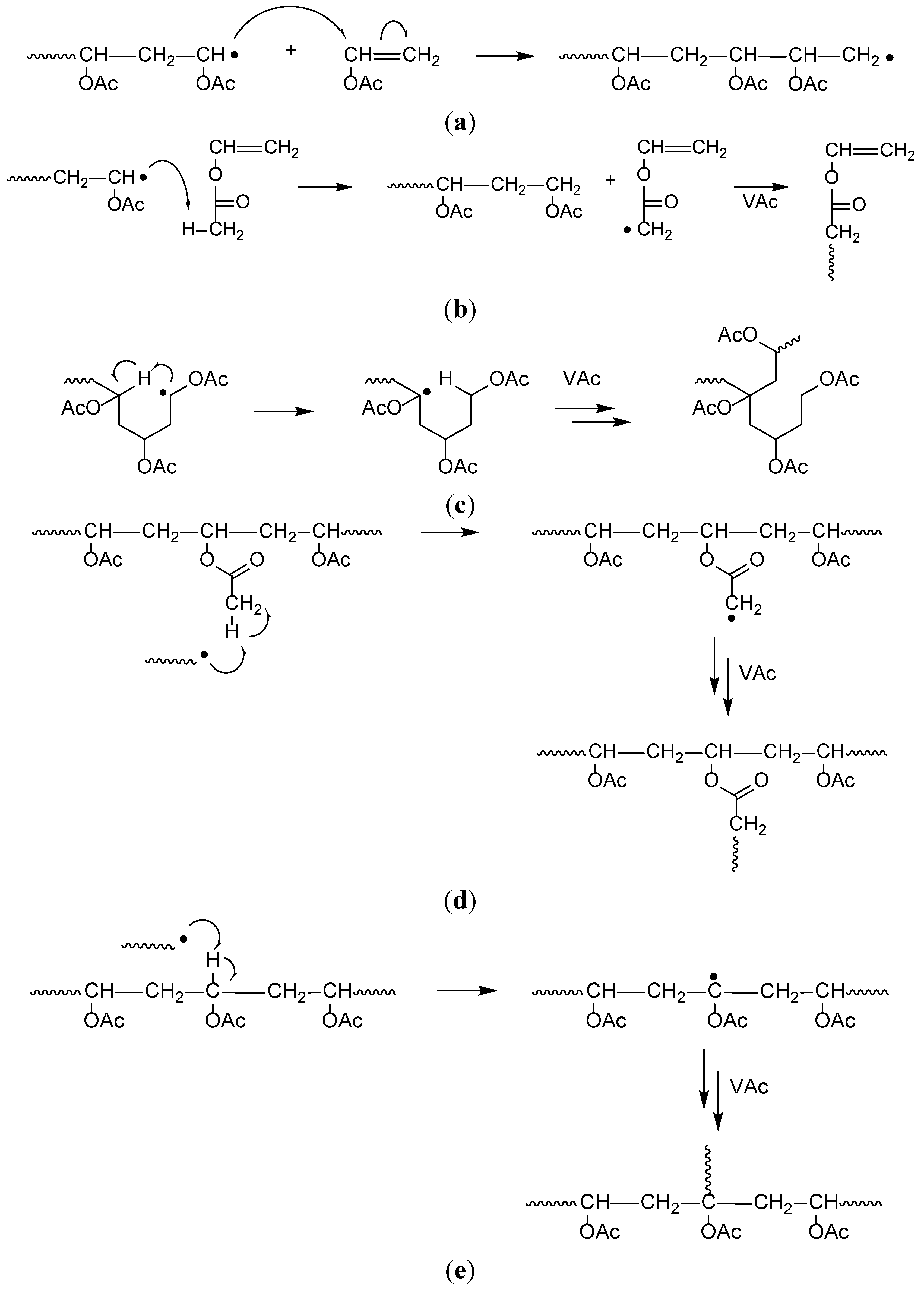

Ethylene vinyl acetate polymerization mechanism.

Eva copolymers are commercially used predominantly in the areas of coating laminating and in the film industries.

The effects of temperature pressure added co solvent vinyl acetate feed rate and emulsifier type and concentration on the rate of polymerization cumulative copolymer composition molecular.

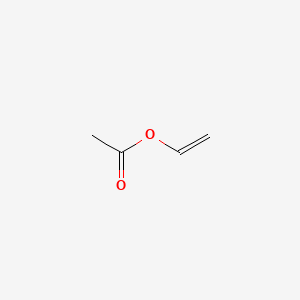

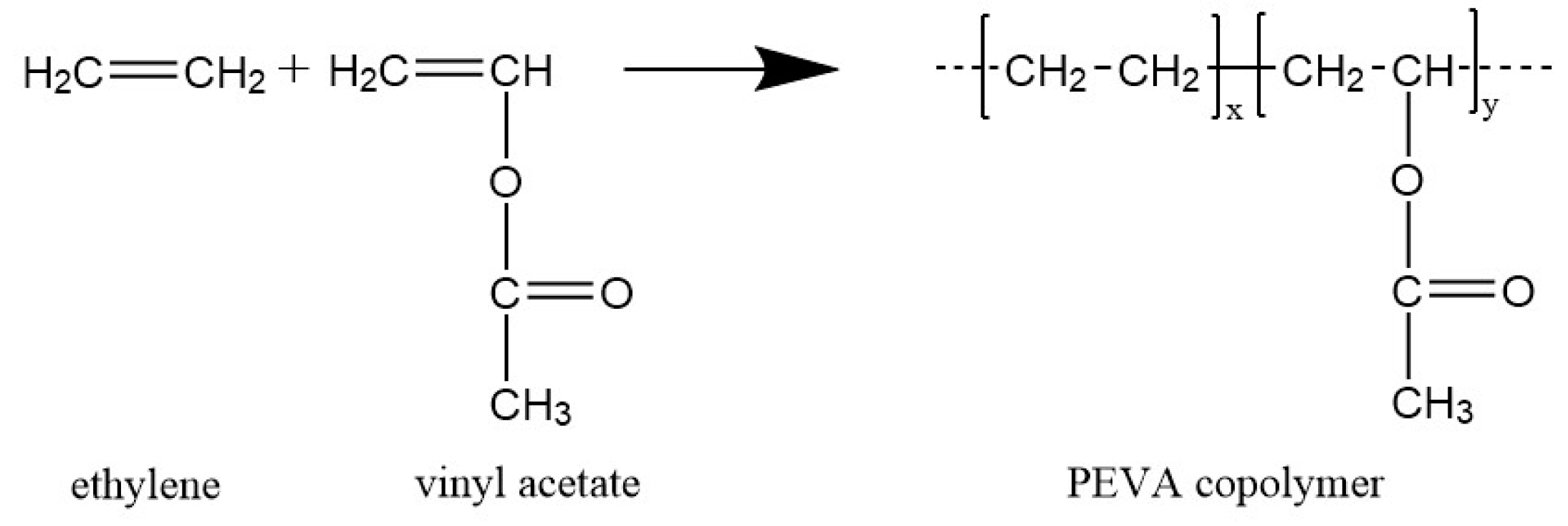

Ethylene vinyl acetate eva also known as poly ethylene vinyl acetate peva is the copolymer of ethylene and vinyl acetate the weight percent of vinyl acetate usually varies from 10 to 40 with the remainder being ethylene.

The polymerization reaction is initiated by forming alkene metal complex.

Therefore vinyl acetate runaway polymerization incidents are very serious and they occur with a high frequency.

The polymerization of vinyl acetate is probably the second most frequent cause of runaway reaction accidents in the chemical industry after the phenol formaldehyde runaway reaction.

This method involves the gas phase addition of acetic acid to acetylene in the presence of metal catalysts.

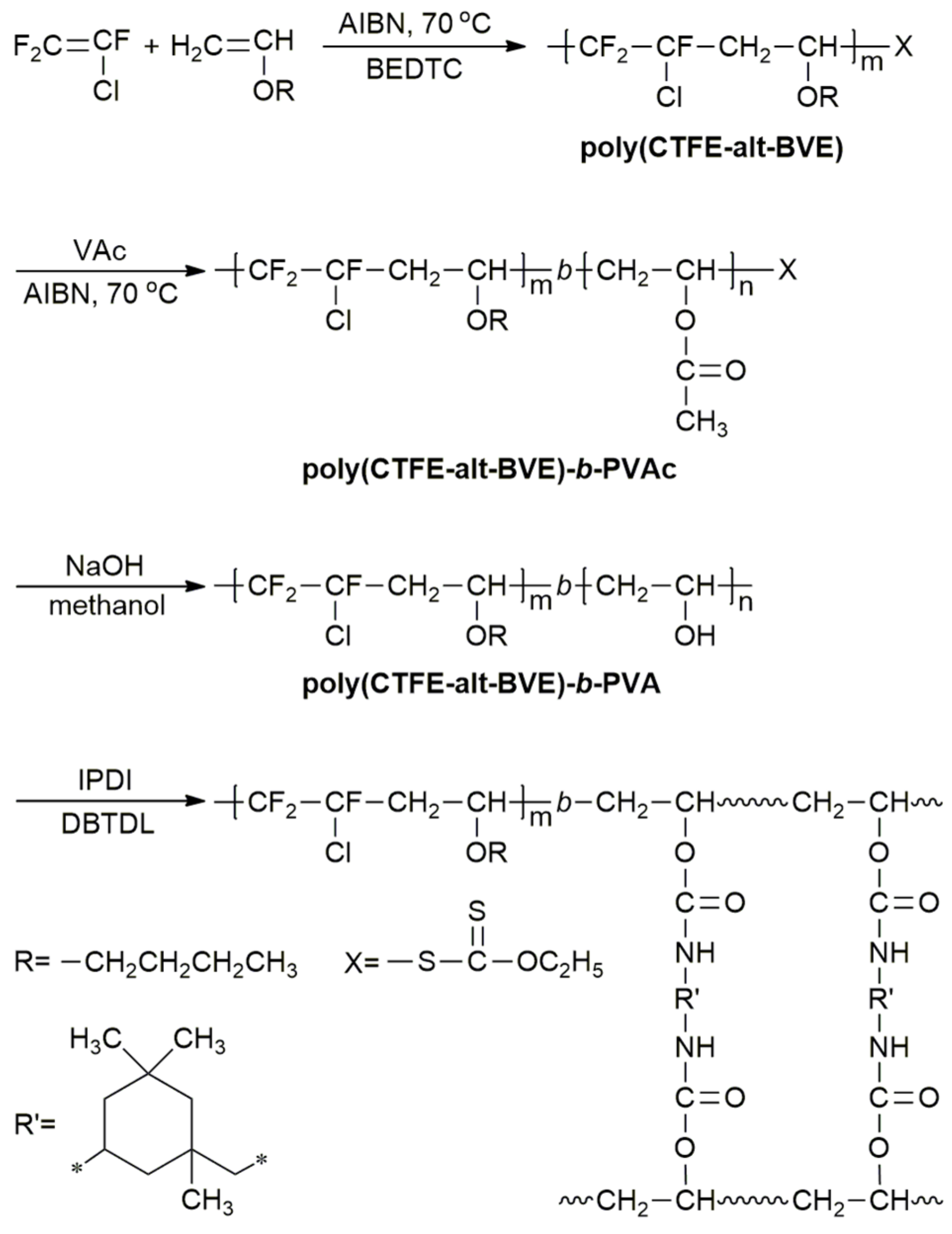

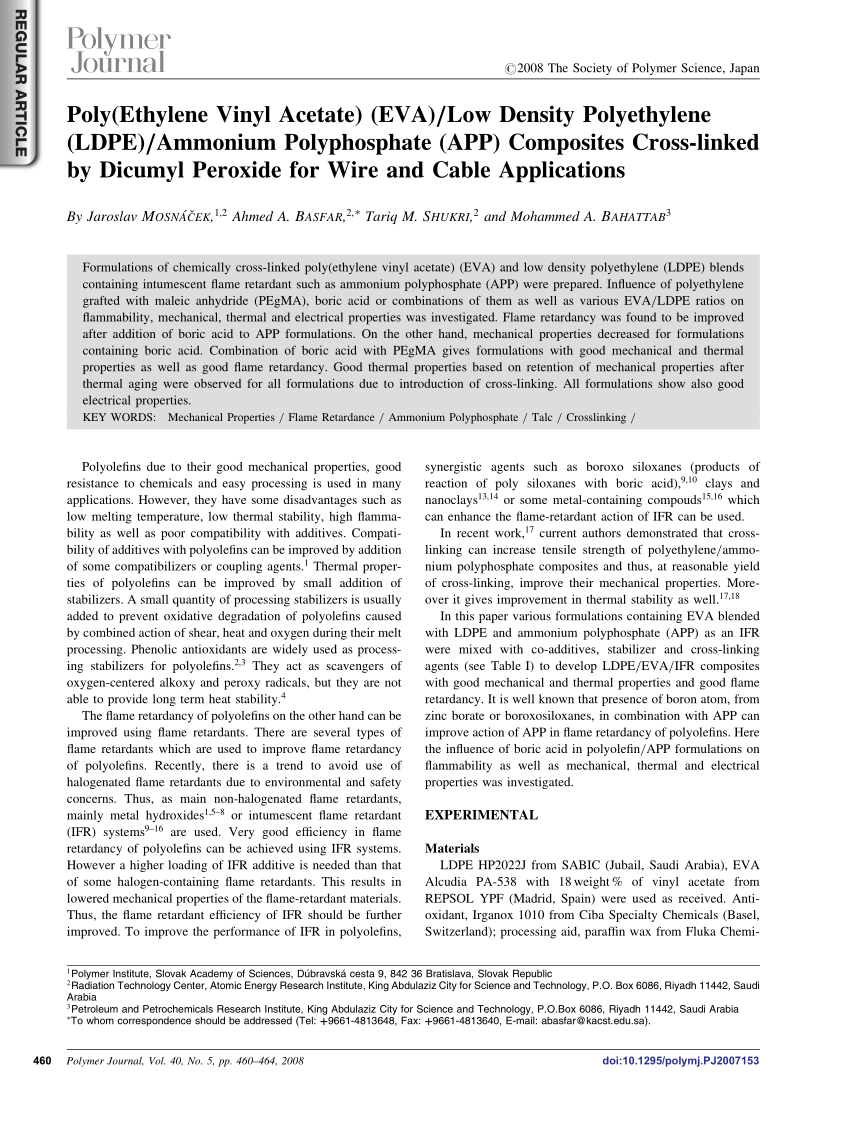

12 8 1 ethylene vinyl acetate eva is a copolymer of ethylene and vinyl acetate va segments typically formed via free radical polymerization.

Coordination copolymerization of vinyl acetate vac with ethylene leading to linear copolymers that possess in chain ch 2 ch oac units has been accomplished using novel palladium complexes bearing alkylphosphine sulfonate ligands.

Eva generally contains 1 50 of the va comonomer along the carbon chain backbone.

There are three different types of eva copolymer which differ in the vinyl acetate va content and the way the materials are used.

By this route using mercury ii catalysts vinyl acetate was first prepared by fritz klatte in 1912.

The copolymerization by itp itcop of ethylene with vinyl acetate vac to form poly ethylene co vinyl acetate eva copolymer was also successful.

In the production of ethylene vinyl acetate copolymers in a free radical catalyst initiated high pressure process explosive decomposition is prevented by contacting the reactor effluent downstream.

Vinyl acetate was once prepared by hydroesterification.

.jpg)