The food and drug administration fda has stated that ethylene vinyl acetate is safe when used in food production packaging or transportation and it s not an especially dangerous material.

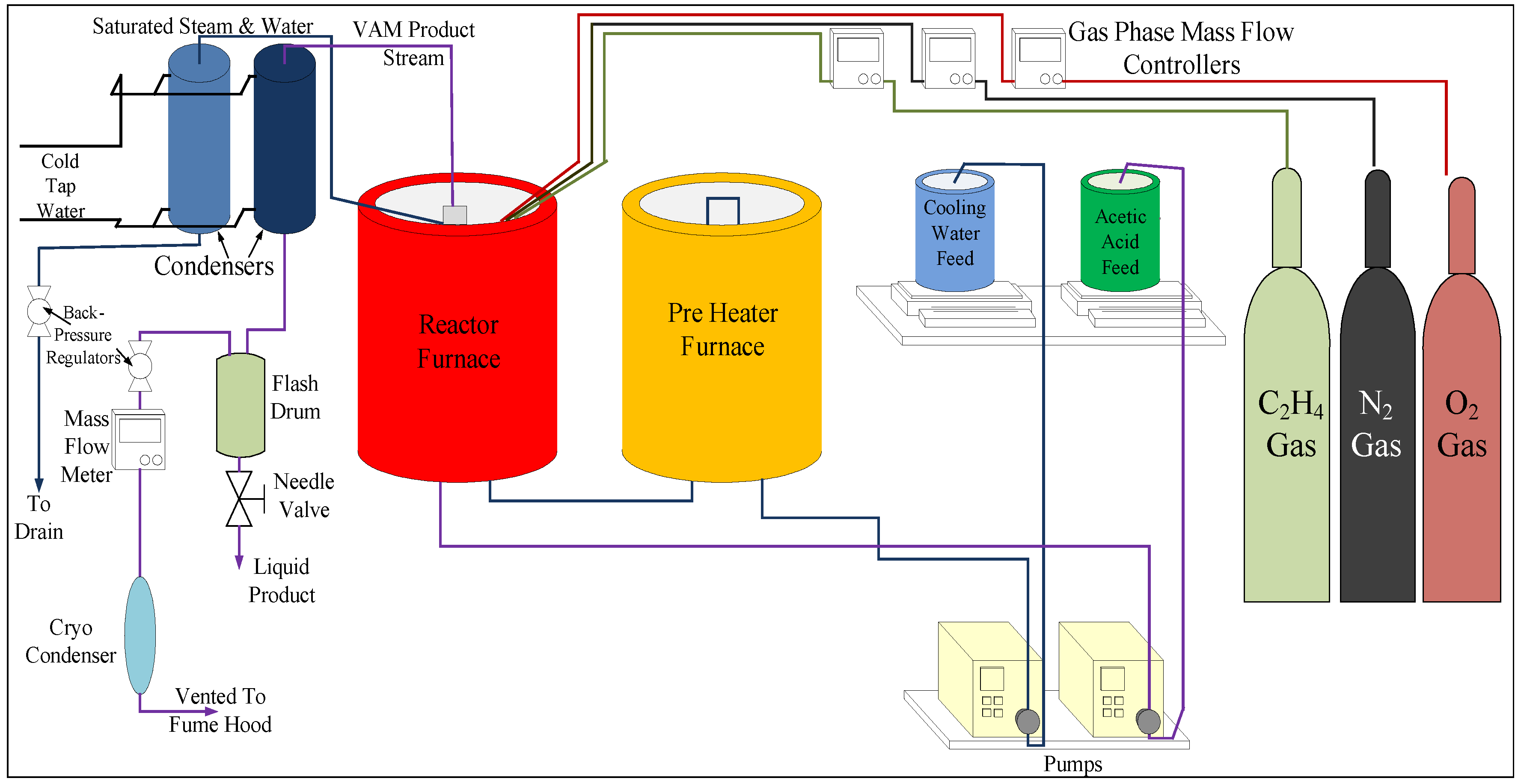

Ethylene vinyl acetate manufacturing process.

Since vinyl alcohol is highly unstable with respect to acetaldehyde the preparation of vinyl acetate is more complex than the synthesis of other acetate esters.

Ethylene vinyl acetate eva is a copolymer that is manufactured from ethylene and vinyl acetate monomer vam.

Intratec provides ethylene vinyl acetate pricing data covering 13 years of historical prices and forecasts.

Vinyl acetate ethylene vae emulsions are based on the copolymerization of vinyl acetate and ethylene in which the vinyl acetate content can range between 60 and 95 percent and the ethylene content ranges between 5 and 40 percent of the total formulation.

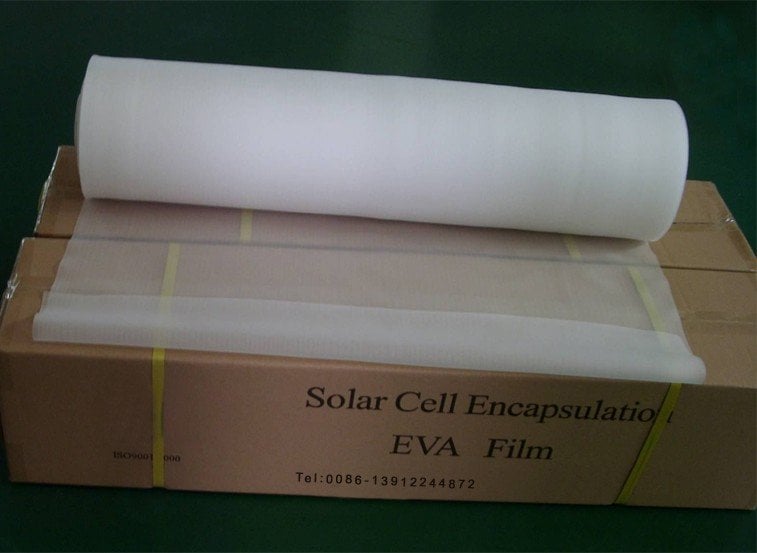

Ethylene vinyl acetate is a type of plastic a polymer with a wide variety of uses both residential and industrial.

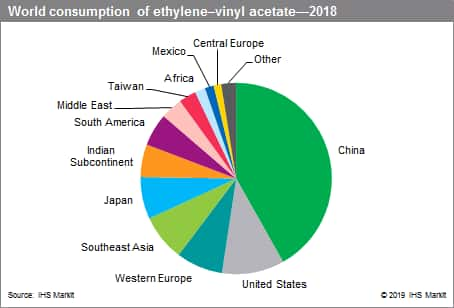

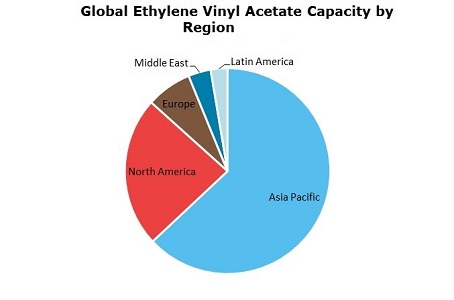

Process economics program report 155b published september 2012 despite the threat of linear low density polyethylene lldpe resin substitution global ethylene vinyl acetate eva copolymers consumption continues to grow with new capacity expansions expected.

See a sample below or register for free to see much more.

A predetermined amount of the strips are placed into a first mold unit which is heated.

A process for producing an ethylene vinyl acetate insole involves weighing molding compounds for manufacturing the ethylene vinyl acetate insole.

Acetylene based technology was used first in the commercial production of vam with the gas phase process preferred to the liquid phase reaction.

Subscribers to our commodity price database have access to ethylene vinyl acetate and as much as 217 other commodities prices across several countries from main world regions.

Ethylene vinyl acetate eva also known as poly ethylene vinyl acetate peva is the copolymer of ethylene and vinyl acetate the weight percent of vinyl acetate usually varies from 10 to 40 with the remainder being ethylene.

The main advantages of eva is that it has good toughness flexibility clarity and gloss the ability to withstand low temperatures and good tear resistance.

The sheet material is cut into a plurality of elongated strips.

Vinyl acetate is the acetate ester of vinyl alcohol.

The major industrial route involves the reaction of ethylene and acetic acid with oxygen in the presence of a palladium catalyst.

Ethylene has now become the preferred feedstock with the gas phase route used due problems of corrosion and byproduct formation when.

There are three different types of eva copolymer which differ in the vinyl acetate va content and the way the materials are used.