Ethylene vinyl acetate is a plastic made by combining ethylene and vinyl acetate.

Ethylene vinyl acetate foam environmental impact.

Ethylene vinyl acetate or eva material is an elasticized closed cell foam with rubber like softness and flexibility.

Added during the manufacturing process ecopure enhances the biodegradability of eva plastics and shortens the time plastics that have been disposed of.

This formulation is more flexible than low percentage vinyl acetate.

The food and drug administration fda has stated that ethylene vinyl acetate is safe when used in food production packaging or transportation and it s not an especially dangerous material.

Vinyl acetate is a clear colorless liquid.

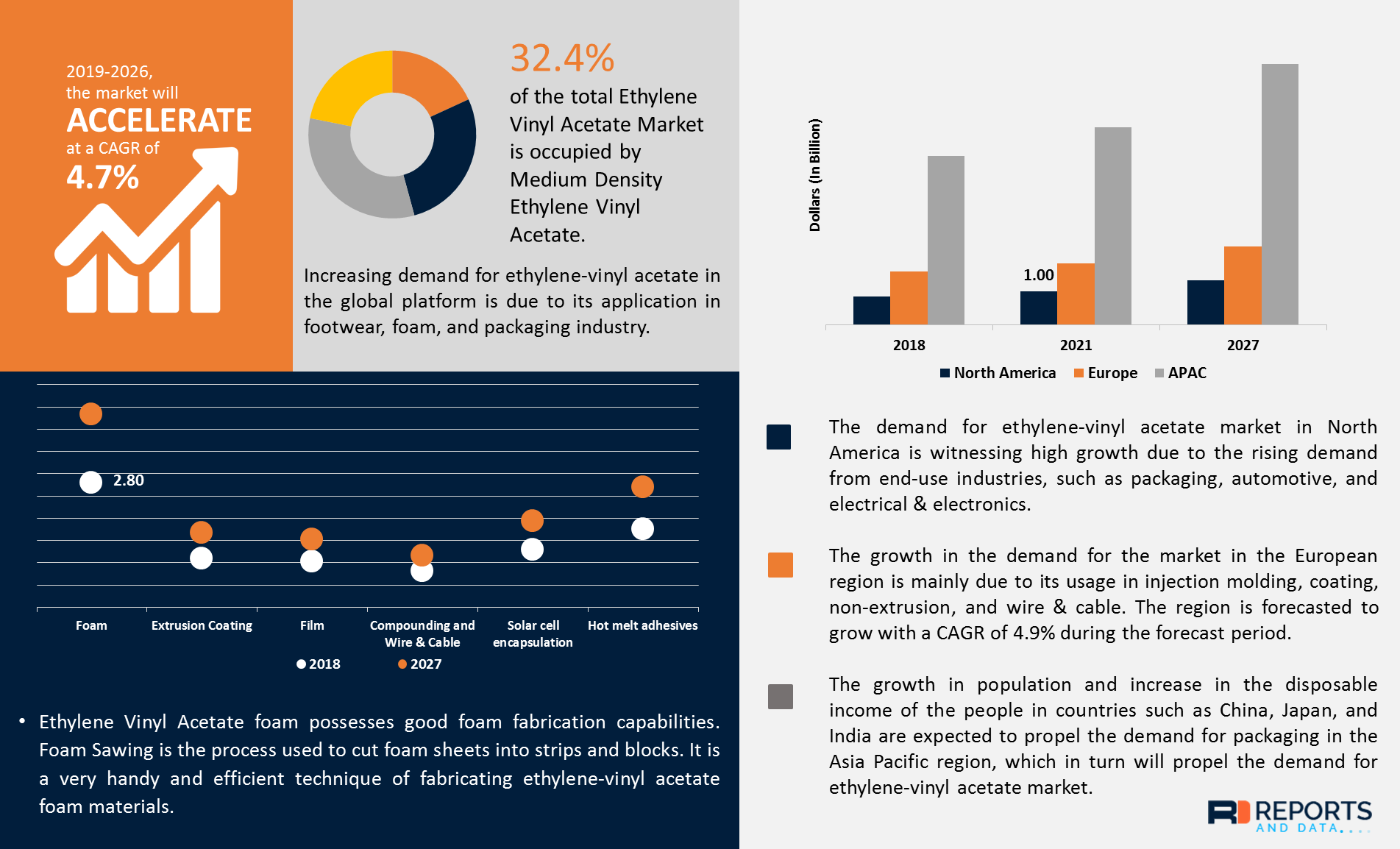

There are three different types of eva copolymer which differ in the vinyl acetate va content and the way the materials are used.

Although the synthetic polymer is a useful material for the athletic shoe industry it has become an environmental concern because of its poor biodegradability.

Eva can also be made into eva foam with the use of a plasticizer.

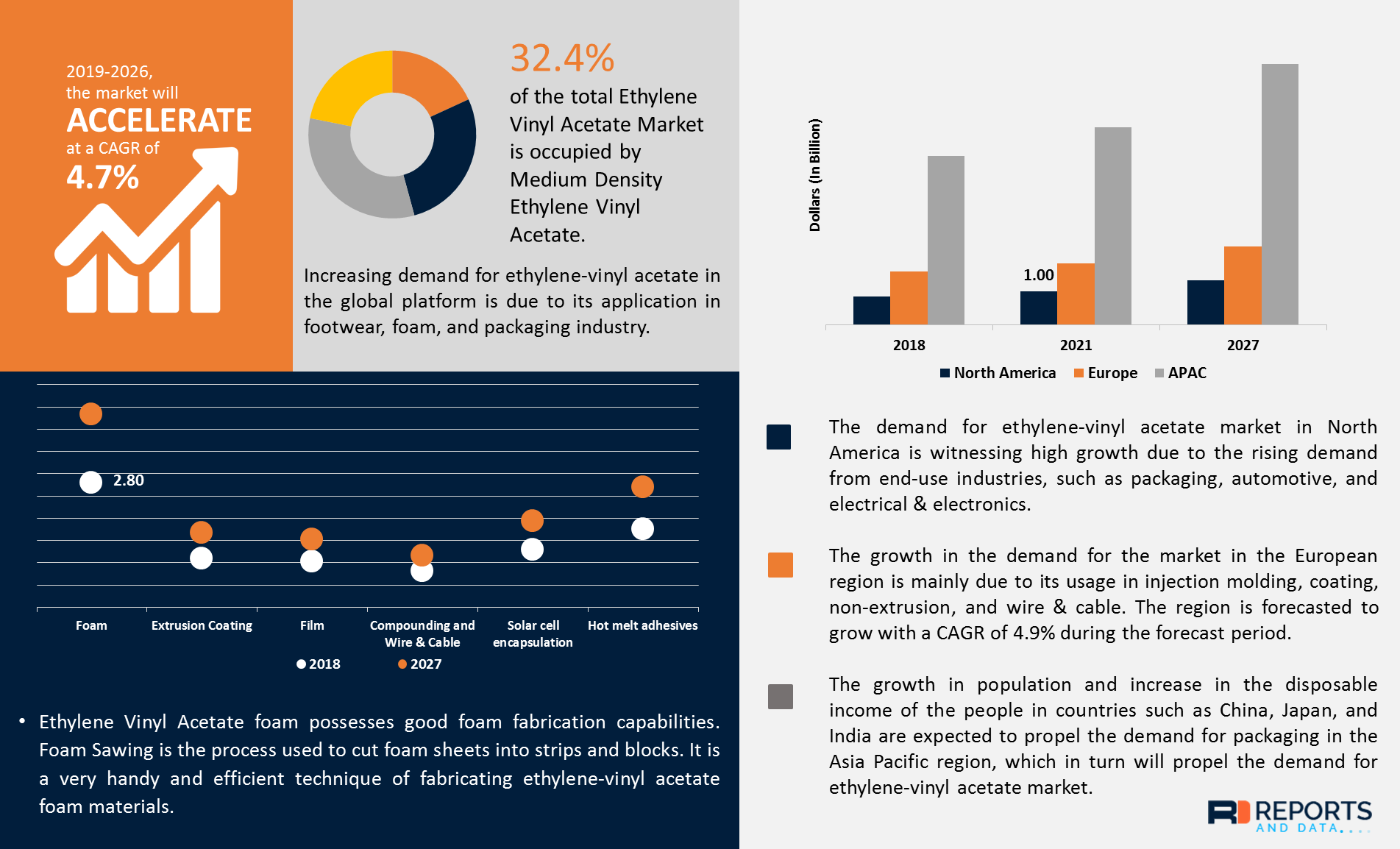

Eva is used in several applications thanks to the varied properties it possesses.

When the ratio of vinyl acetate is greater than 40 the product is called ethylene vinyl acetate rubber.

Eva shows good barrier and stretch properties.

This is the most flexible and versatile formulation.

Evas release volatile organic compounds vocs into the air when decomposing.

It shows good chemical resistance.

Ethylene vinyl acetate properties ethylene vinyl acetate is a flexible and transparent thermoplastic.

Ethylene vinyl acetate eva also known as poly ethylene vinyl acetate peva is the copolymer of ethylene and vinyl acetate the weight percent of vinyl acetate usually varies from 10 to 40 with the remainder being ethylene.

It has a sweet pleasant fruity smell but the odor may be sharp and irritating to some people.

Biodegradable ethylene vinyl acetate eva plastic is the copolymer of ethylene and vinyl acetate polymers.

It s considered to be a safe alternative to pvc.

Eva mats will have a glossy appearance and are resistant to uv radiation and cracking.

It s very soft and elastic and it can be made into a plastic that s like rubber yet extremely tough.

Eva is a polyolefin copolymer of ethylene and vinyl acetate that provides durability and flexibility making it the most commonly used material found in athletic shoe midsoles.

It readily evaporates into air and dissolves easily in water.

Most shoe midsoles from the major running shoe companies are derivatives of eva ethylene vinyl acetate foam with additives such as polyurethane to create the desired results of the individual shoe brand.

The outstanding versatility of eva foam is of.

High percentage vinyl acetate.

Ethylene vinyl acetate is a type of plastic a polymer with a wide variety of uses both residential and industrial.

Ethylene vinyl acetate offers good low temperature flexibility.

Eva is flexible has good clarity and is resistant to ultraviolet radiation.